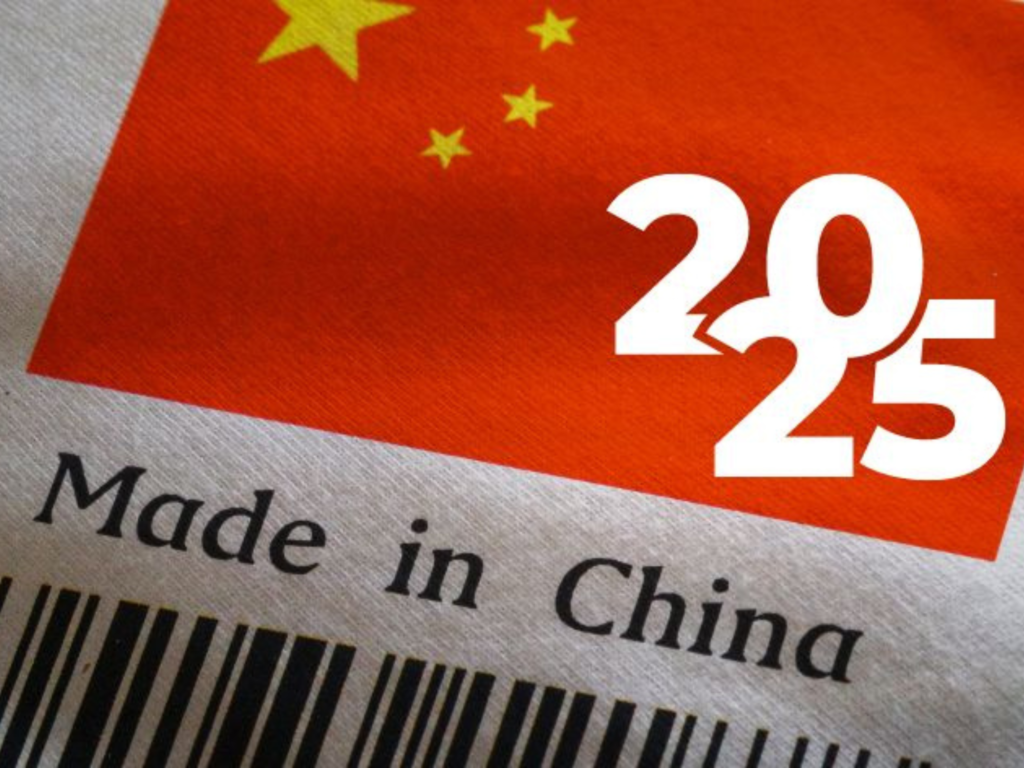

US Tariffs Force Chinese Factories to Halt Production, Seek New Markets

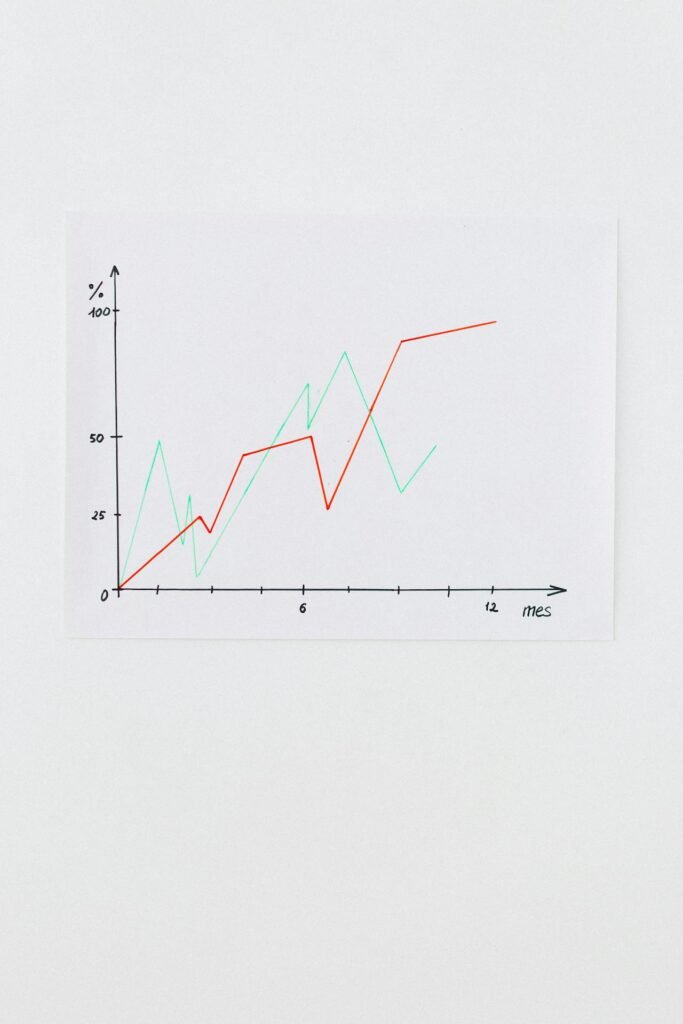

A wave of factory shutdowns is sweeping through China’s industrial heartlands as U.S. tariffs render exports uncompetitive, forcing manufacturers to either relocate production or pivot to new markets. According to China’s Ministry of Industry, over 4,200 factories suspended operations in Q1 2025—a 35% increase from 2024—with electronics, textiles, and automotive suppliers hardest hit.

Key Developments:

-

Electronics Exodus: Foxconn is shifting 30% of iPhone assembly to India, while Xiaomi accelerates Vietnam expansion.

-

Textile Retreat: Zhejiang garment producers report 50% order declines, pushing 1,200 SMEs toward bankruptcy.

-

Auto Sector Pivot: BYD halts two U.S.-bound EV production lines, redirecting output to Southeast Asia and the Middle East.

Strategic Shifts:

-

Nearshoring to Mexico: 380 Chinese auto parts firms opened Mexican facilities in 2024.

-

Africa Push: Huawei and Transsion dominate smartphone markets in Nigeria and Kenya with localized production.

-

Domestic Consumption: Alibaba reports 22% growth in rural e-commerce as factories target inland provinces.

Expert Insight:

“These tariffs have broken the ‘China as world’s factory’ model,” says MIT economist David Autor. “We’re witnessing the fastest global supply chain rewrite since WWII.”

What’s Next?

The State Council’s “Dual Circulation 2.0” plan aims to boost domestic R&D spending to 3.5% of GDP by 2027, reducing export dependence.